Stress analysis is a cost saving tool that gives the possibility to test a product before proceeding with costly manufacture. The tests can comprise of applications of force, pressure, prescribed displacement (finding what force applied leads to a determined deflection), torque and temperature.

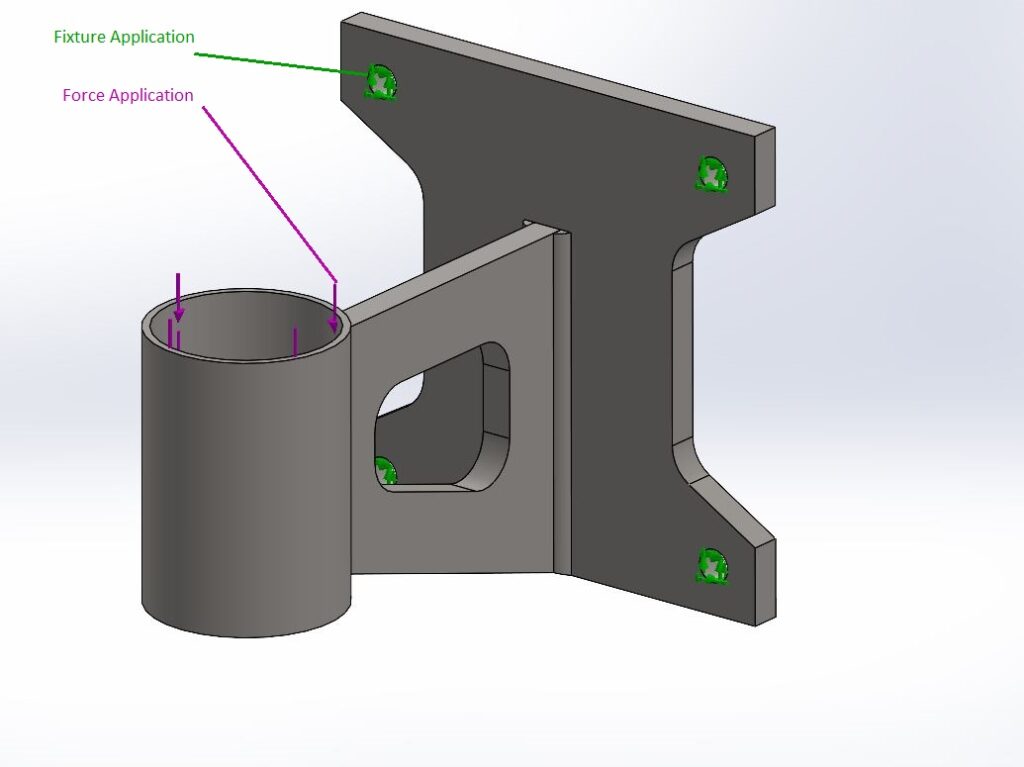

The part I process is designed, modelled and then evaluated with the FEA software (Solidworks simulation). A fixture is applied to the part. This is usually where the part is bolted, welded or fixed in any other way.

An external load is applied, this is typically representative of the part being employed in its typical use scenario, in terms of load type and direction etc.

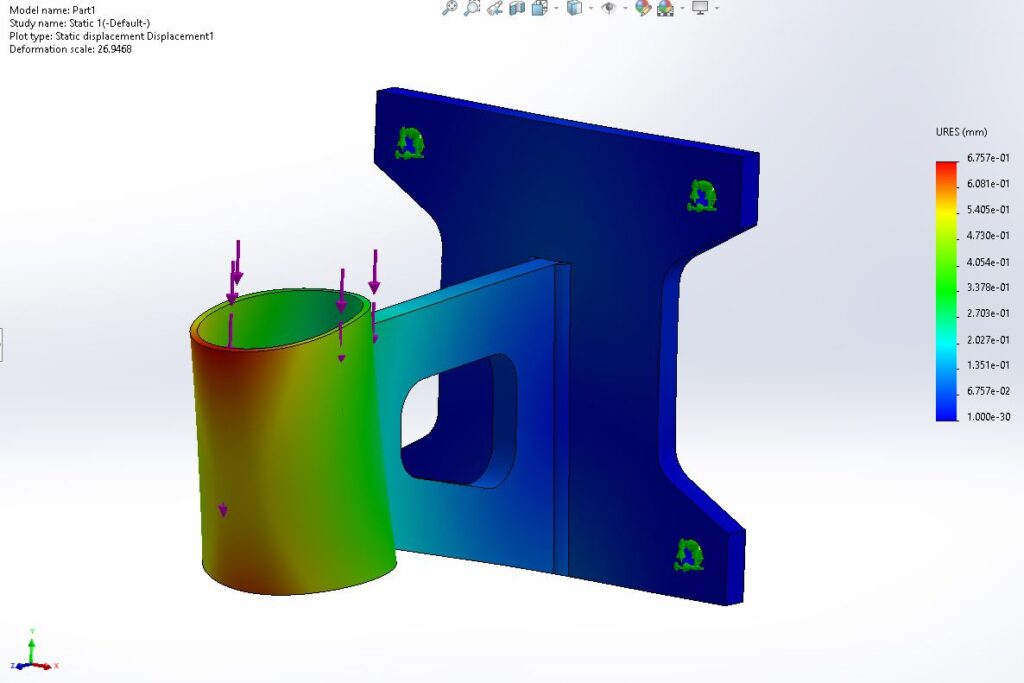

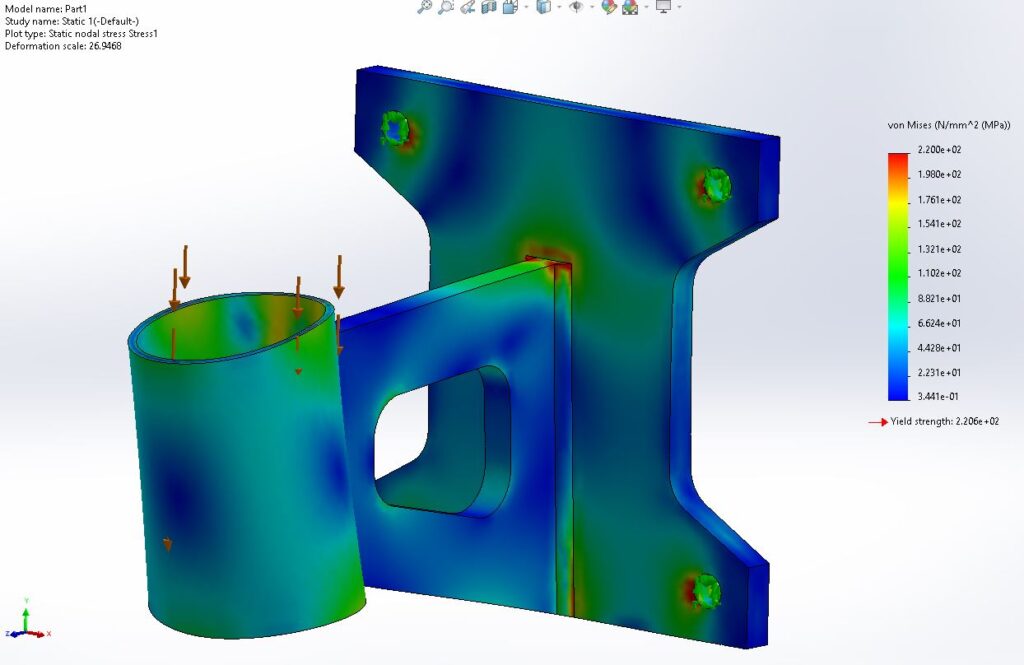

Once these factors have been decided, the software can run the scenario and output both stress and deflection results to a 3 dimensional gradated representation.

I find most utility for stress analysis in cost reduction, weight reduction and using materials which are viable for the design.