Stress analysis serves as a valuable cost-saving tool by allowing engineers to test a product before committing to expensive manufacturing. These tests typically involve applying force, pressure, prescribed displacement (to determine the force required for a specific deflection), torque, and temperature.

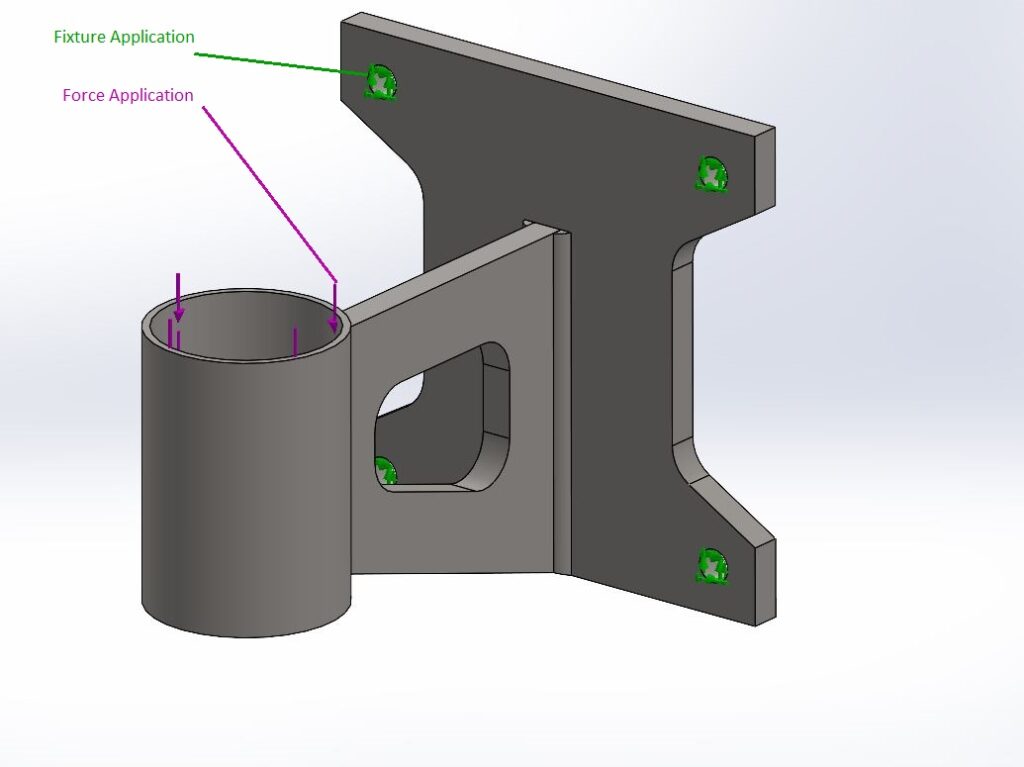

In my process, I first design and model the part before evaluating it using FEA software (SolidWorks Simulation). Afterward, I apply a fixture to the part, usually at the points where it is bolted, welded, or otherwise secured.

An external load is applied to simulate the part’s typical use scenario, considering factors such as load type and direction.

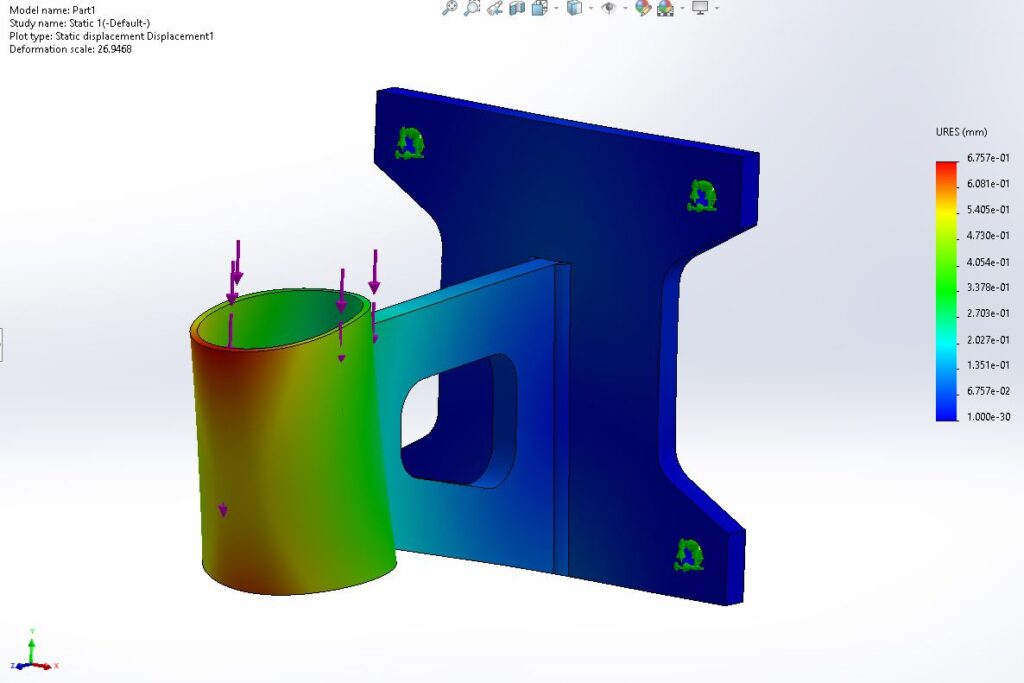

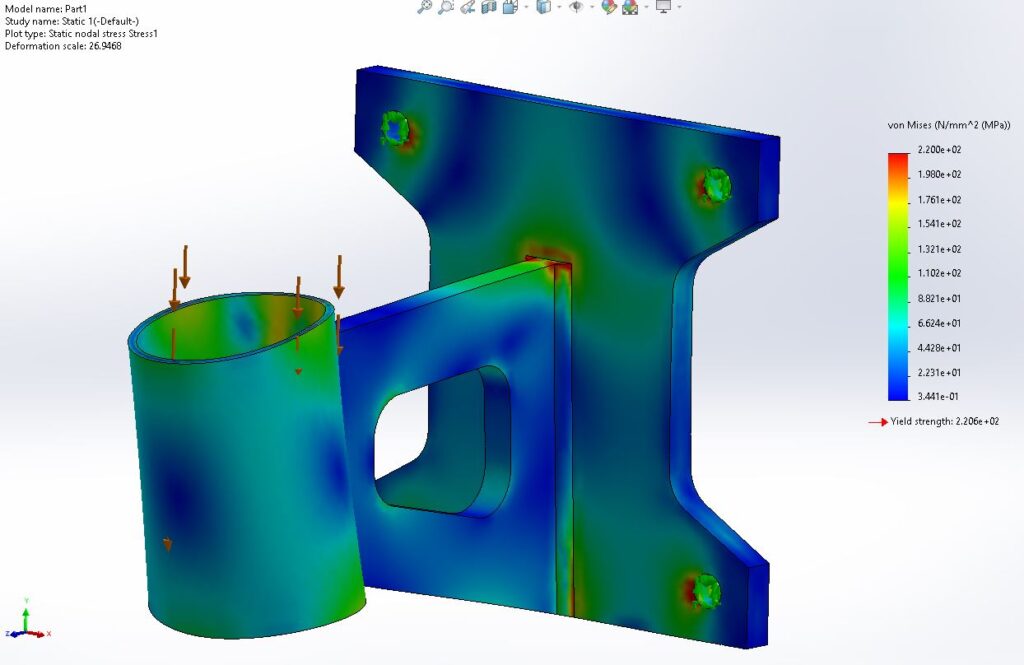

Once these parameters are set, the software runs the simulation and generates a three-dimensional, gradated representation of both stress and deflection results.

FEA simulation offers significant commercial and practical benefits. It reduces development costs by identifying potential design flaws early, minimising the need for physical prototypes. By optimising material usage and ensuring structural integrity, it also lowers manufacturing expenses. Additionally, FEA accelerates product development by providing quick, data-driven insights, reducing trial-and-error cycles.

From a practical standpoint, engineers can test products under various real-world conditions without physical testing, improving safety and reliability. The ability to refine designs before production enhances performance and extends product lifespan. Ultimately, FEA supports innovation while saving time and resources.

Solidworks has provided a video demonsrating the use case scenario: https://www.solidworks.com/media/solidworks-simulation-failure-mode-analysis-vibration?_gl=19wq77d_upMQ.._gaMTY1NDMxMTQxOS4xNzQwMTM3NDU3_ga_TPGKGE8GTGMTc0MDEzNzQ1Ni4xLjAuMTc0MDEzNzQ1Ni4wLjAuMA.._ga_XQJPQWHZHH*MTc0MDEzNzQ1Ni4xLjAuMTc0MDEzNzQ1Ni4wLjAuMA..